Features:

Clamping Unit

·Five

pivots hyperbolic toggle clamping mechanism has characteristics with fast

opening and closing, stable and energy saving through the optimized design.

·With Differential high speed mould locking function, it can effectively

shorten the molding cycle time and improve the work efficiency of the machine.

·The mould plate adopts the finite element technology on structure auxiliary

analysis, that makes the mould plate structure more reasonable, strength and

resistance to fatigue better, extending service life;

·High rigidity ant fraying tie bars plated with hard chromium has advantages of

high precision, high strength, high strength and long life.

·Reliable low pressure protection function greatly prolongs the service life of

the mould.

·The clamping and ejecting stroke of the mould are controlled by high precision

electronic sensor, the setting precision can achieve + / - 0.1 mm. Low pressure

protection and ejector stroke set get more directly and simply.

·The protection devices of mechanical, hydraulic and electrical ensure that the

operating personnel is safety, and fully embody enterprise culture with

human-oriented. (Note: Size above BJ400 machine, the hydraulic safety

protection device is the standard configuration.)

·To control lubrication system automatically according to how many times to

open and close the mould, the automatic quantitative lubrication system can

guarantee the clamping machine more stable, reliable, and longer life.

·Hydraulic motor with gear adjustable system, makes mold adjustment more

reasonable and perfect.

Injection Unit

·High efficient separation type screw, high mixing screw and all

kinds of special screws improve the applicable scope of the material and

guarantee molten material uniform and measurement stability.

·Duplex balanced injecting device provides higher injection pressure, makes the

unit more simple and stable, and lowers the failure rate. It is more convenient

to maintain and save space meanwhile.

·Machines above BJ288 with double injection shift cylinder accept the stress

more reasonable and effectively prevent the nozzle deviation, avoid material

leakage.

Features of

hydraulic system

·High precision computer control PLC is combined together

perfectly with high efficiency and energy saving proportion plunger type

variable pump, saves electricity to 25 ﹪ - 50 ﹪, the economic benefits and social benefits are double increased.

At the same time it can lower the oil temperature and less cooling water

consumption and prolong the service life of hydraulic components, reduce the

failure rate, save the maintenance cost.

·High precision returned oil filter can effectively prevent hydraulic oil

pollution and deterioration with effect of NAS - level 7, full flow oil filter.

Therefore, there is no need to change oil, which not only saves the cost for customers

, but also ensures the hydraulic system running more smoothly and the sealing

parts working longer.

·Imported high-grade hydraulic components fitting with differential oil circuit

design guarantee rapid, stable, low noise of the mould clamping. It can shorten

the molding cycle time and improve the production efficiency.

·The oil circuit system is designed with mass flow and plug-in valve , which

not only ensures that the system has rapid response and small impact, but also

reduces the oil pressure loss.

·Spiral guide cooler in high thermal efficiency and low pressure loss ensure

the stable operation of hydraulic system; improve the repetition accuracy and

the product yield.

·The screw is driven by Low speed and high torque hydraulic motor, which can

meet the plasticizing requirements of various raw materials.

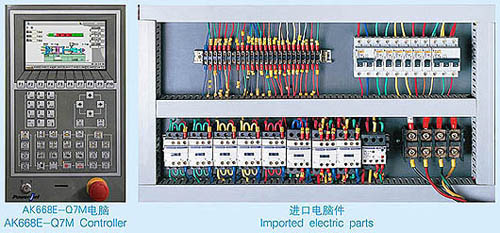

Electric

Controller

·High

performance of switching power supply can normally work with operating voltage

from 160v to 280v , which can be adapted for all kinds of bad power

environment;

·Using high pixel (800 x 480) large capacity TFT true color display, it makes

the display content more rich, the process adjustment more intuitive , the

operating more simple and the function more perfect. It also can simulate

machine action.

·High-speed CPU with increased capacity storage not only meets the requirements

of the process control system, but also can use graphic to record complete

injection process, make the injection process control to be more convenient.

·Large capacity storage make monitoring, alarm, mould parameters store capacity

multiplication, can store 200 sets of mould injection data, can record 200

constitutive monitoring data and 200 times alarm information. Mold data can

choose copy or clear freely. At the same time, it still can use SD card to read

and store the mould data that is more conducive to mass production management.

·Equipped with internet communication port, injection molding machine can be

realized network management, can be real-time monitoring factory production

status and the working condition of injection molding machine, to realize the

factory automation production.

·Perfect automatic monitoring and a large number of internal parameters, can

assist you to adjust machine’s every movement to the best condition.

·Six sections injection speed, pressure and three sections of holding pressure,

speed control, can satisfy all sorts of complex products process conditions.

·Three sections of the charging speed, pressure control, ensure the

plasticizing more uniformity, faster and more stable measurement.

·Rapid temperature control system, using FUZZY control mode, has the faster

warming, high precision characteristics, temperature control accuracy reach to

±1 ℃ in static time.

At the same time it provides high low temperature deviation alarm and

thermocouple bolt check out.

·Function to prevent cold material start-up.

·Mold locking, injection and ejector stroke use high precision electronic

sensor to control the position, the setting accuracy in +/- 0.1 mm.

·Supported with ejector stay, thimble shock and multiple ejector function. the

speed and pressure of thimble forward/backward can be divided into two stage

control.

·Forming number settled with automatic stop, which is more convenient for

production management.

·Defective products monitoring: when machine operates in automatic mode , the

computer will be for each cycle injection monitoring, to judge product and

machine normal or not.

·Automatic Adjustment Mode: can direct input clamping pressure, the mold

thickness will be adjusted by computer automatically, that makes the clamping

force to be in accord with high clamping pressure.

·Data setting lock prevents improper personnel change.

Features of

lubrication system

·Major

friction parts are equipped with lubrication points. Central oil supply system

is used for hinges. Electric lubricant pump controlled by computer sends

automatically lubricating oil (grease) to lubrication points. Lubrication is

simple and high efficient.

·Intelligent volumetric centralized lubricating system, controlled by computer,

sends quantitatively lubricating oil (grease) to wearing points, and guarantees

that the key carrying surfaces are lubricated reliably. The repair is visual,

convenient and fast. The service life of the machine is longer.

Standard devices

1 Injection system

. Nitriding alloy steel screw charging barrel

. Standard injection nozzle

. Double cylinder balance injection unit

. Mobile hopper

. Anti-cold start-up of screw

. Automatic dislodging function

. Anti flow casting function

. Multistage charging barrel PID temperature control

(4-7stages)

. Automatic inspection on material molten and material injection fault

. Precision electronic meter control on material injection/molten stroke

2 Mould locking device

. Precision electronic meter control mould locking / thimble travel

. Mould locking three plates / Mould plate & toggle

adopt high rigid nodular cast iron.

. Two stages ejector forward / backward movement controlled by computer

. Mould low pressure protection function

. Hydraulic mould adjusting device

3 .Hydraulic system

. High performance proportional variable pump system

. Molten material back pressure adjusting device

. Full flow precision return oil filter

. Automatic adjustment of system pressure and flow

4 .Control system

. Input / output viewing function

. Setting function of automatic temperature retaining and heating

. Time / position /

pressure, three conversion modes

. Independent adjustment on slope of each movement

. Two-sets of hydraulic core pull / un-screwing mould release

5. Operation manual

. Tool box

. Spare parts

Optional configuration

1 .Injection system

. Long injection nozzle (Extended by25 / 50 / 100mm)

. Special screw & Barrel

. Hopper dryer

. Charging barrel air blowing device

. Injection nozzle protective cover

2 .Mould locking system

. Enlarged mould capacity by 50/100mm

. Super large ejector stroke

. Mould hoisting carrier

. Mould heat insulating plates

. Special mould location ring

. Pneumatic safety door

3 .Hydraulic system

. Hydraulic core pull / un-screwing mould release device

. Hydraulic safety protection

. Independent oil temperature control system

. Sensitive servo injection system

. Closed-loop control variable pump system

. Nitrogen material injection device

. Melt

proportional back pressure control

4 .Control system

. Electric un-screwing mould release device

. Multiple-unit

mold air blowing devices

. Electric rotating mould release dynamic interface

. Change power supply voltage

Note

.Theory injection capacity = screw diameter2×π/4×screw

travel

.Actual injection capacity is the maximal weight of polystyrene (

PS ) raw material injected to air.

.When UPVC, PC, PMMA, PA and other engineering plastic material

are used, please let us know. When you need modifying parameters and functions

of the machine, please let us know also.

.According to demand of machine upgrade, we will change technical

parameters, configuration of some parts and service’s items without prior

notice.

.Photos are for reference only. If there is any difference with

actual products purchased, the real products are final.

.In normal condition six months warrantee for barrel & screw;

but using caustic or any recycling material is not guaranteed.

Parameter

|

Type

|

HD10000-8350

|

HD6800-5427

|

HD3300-1902

|

HD4000-2499

|

HD900-300

|

HD5000-3514

|

|

CLAMPING UNIT

|

T-shot platen

|

|

|

|

|

|

|

Clamping

force, KN

|

10000

|

6800

|

3300

|

4000

|

900

|

5000

|

|

Opening

Stroke, mm

|

1150

|

930

|

600

|

710

|

320

|

830

|

|

Max. daylight,

mm

|

2300

|

1870

|

1300

|

1400

|

680

|

1680

|

|

Platen Size,

mm*mm

|

1700*1700

|

1340*1340

|

985*985

|

1050*1050

|

540*540

|

1260*1260

|

|

Space between

bars, mm*mm

|

1160*1160

|

930*930

|

670*670

|

740*720

|

360*360

|

820*780

|

|

Max. mold

height, mm

|

1150

|

940

|

700

|

730

|

360

|

850

|

|

Min. mold

height, mm

|

500

|

350

|

300

|

300

|

130

|

300

|

|

Ejector

stroke, mm

|

350

|

265

|

180

|

210

|

100

|

220

|

|

Ejector force,

KN

|

290

|

184

|

77

|

110

|

34

|

135

|

|

INJECTION UNIT

|

|

|

|

|

|

|

|

Screw

diameter, mm

|

100 110 120

|

83 90 83

|

60 68 75

|

68 75 83 90

|

30 36 42

|

75 83 90 100

|

|

Screw L/D

ratio,

|

23 21 19

|

23.5 21 19

|

21 21 19

|

21 20 17.6

17.5

|

20 20 17

|

23.8 21 19.9

17.8

|

|

Injection

Pressure, Mpa

|

205 169 142

|

223 190 154

|

217 169 139

|

208 171 140

119

|

266 185 136

|

204 167 142

115

|

|

Shot volume,

cm3

|

4084 4942 5881

|

2435 2863 3534

|

876 1126 1370

|

1198 1458 1786

2099

|

113 163 222

|

1722 2110 2481

3063

|

|

Shot weight

(ps), g/OZ

|

3838/135

4644/164 5527/195

|

2288/81

2690/95 3321/117.6

|

823/29

1058/37.3 1287/45.4

|

1126/39.7

1370/48.3 1678/59 1973/70

|

106/3.7

153/5.4 208/7.2

|

1619/57.1

1983/70 2332/82.3 2879/101.5

|

|

Injection

rate, g/sec

|

686 830 988

|

400 470 581

|

238 306 372

|

283 344 421

495

|

54 78 106

|

358 439 516

637

|

|

Plasticizing

Capacity, g/sec

|

85 106 121

|

69 86 94

|

57 67 81

|

58 70 80 88

|

13 19 26

|

68 80 88 94

|

|

Screw stroke,

mm

|

520

|

450

|

310

|

330

|

160

|

390

|

|

Screw speed,

rpm

|

115

|

135

|

174

|

122

|

184

|

133

|

|

POWER UNIT

|

|

|

|

|

|

|

|

Hydraulic

system pressure, Mpa

|

17.5

|

17.5

|

17.5

|

17.5

|

17.5

|

17.5

|

|

Pump motor

power, kw

|

55+37

|

55

|

30

|

37

|

11

|

45

|

|

Heater power,

kw

|

42

|

38

|

18

|

22

|

6

|

28

|

|

GENERAL

|

|

|

|

|

|

|

|

Dry circle

time, sec

|

|

|

3.2

|

4

|

1.5

|

5.8

|

|

Oil tank

capacity, L

|

1600

|

1000

|

460

|

630

|

180

|

810

|

|

Machine

weight, kg

|

50

|

32

|

10.8

|

15

|

2.8

|

18.5

|

|

Dimension

(LxWxH)

|

11.0*2.9*3.1

|

9.1*2.4*2.5

|

6.8*1.62*2.3

|

7.2*1.65*2.3

|

3.8*1.1*1.7

|

8.7*2.1*2.3

|

|